- #Changing baud rate in a crestron simpl windows module serial#

- #Changing baud rate in a crestron simpl windows module drivers#

- #Changing baud rate in a crestron simpl windows module driver#

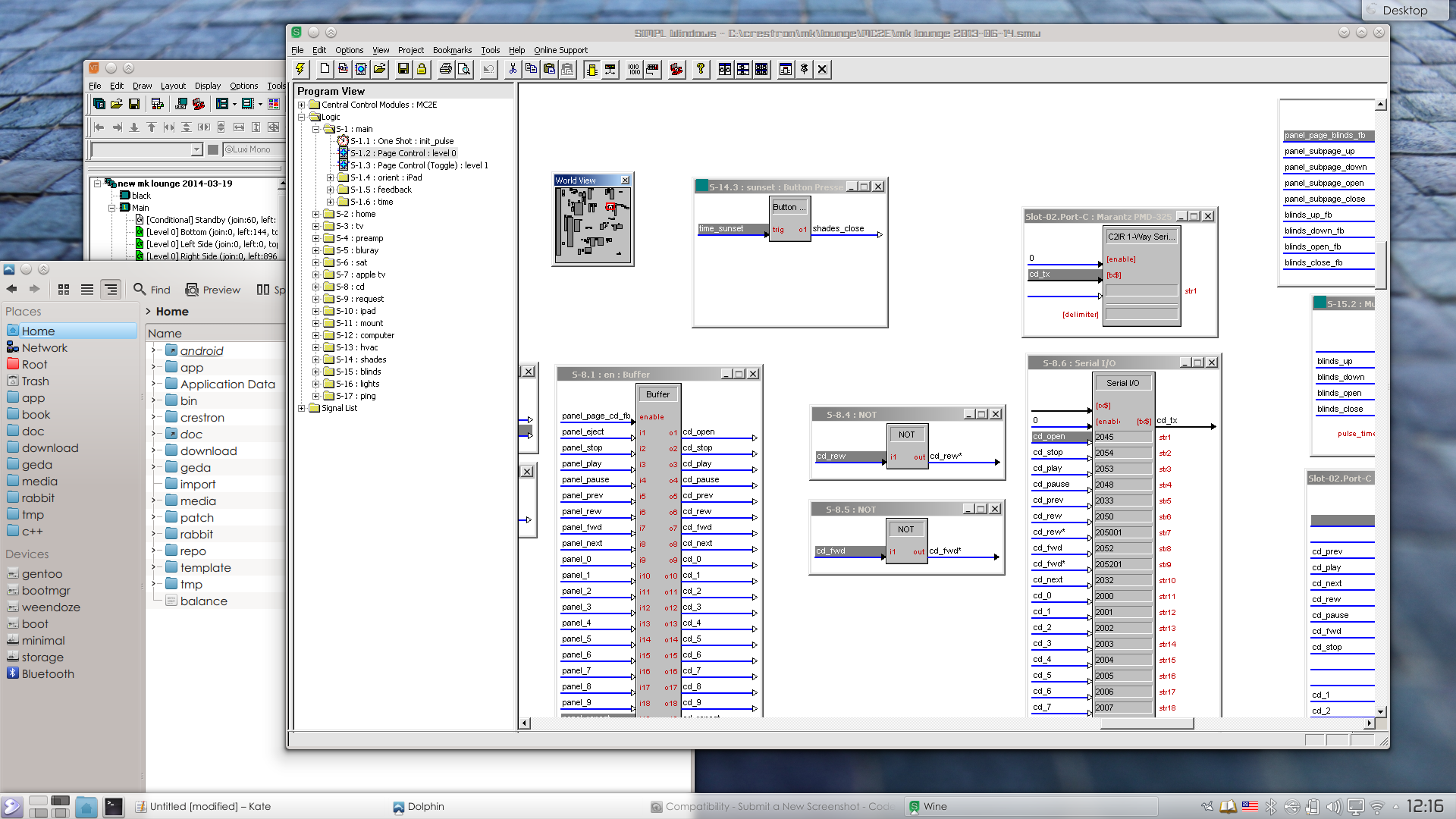

If your ever unsure if X-over cabling is required or if it is straight through do the following. I connect Nec plasma's to Crestron on a weekly basis and i can tell you that the configuration for wiring is 5 wire X-over. Sure you have the Com baud rate and other settings If you wanted to add feedback, polling, this is a good place to start.I have not done a NEC in a while, but I remember Step 6: Save your module, rebuild your user DB, and pray! Step 5: Click in the logic folder > type VIRTUALSERIAL > Fill in the parameter fields for your baud rate, parity, databits, stopbits. Remember to follow Crestron convention for denoting hex characters. There is a parameter window for each join name. Step 4: Fill in the command strings for each individual join. Mark the TX$ output with the join name of TX$. You're going to answer yes to expand the symbol. Make sure you start on the first actual join, the one on the bottom left. You're going to copy and paste the joins from the argument definition onto the joins for the SIO.

#Changing baud rate in a crestron simpl windows module serial#

Step 3: Click the Logic folder in your program view > type SIO or drag a Serial I/O from your Symbol Library - same thing > Open the new symbol. You're going to go down the left side with names such as "Power On" and "Cinemascope". Double click on the Argument Definition symbol in your program view. Step 2: Define your input and output joins.

To make it SB compatible fill out the Device Support tab. Fill out the module information in the window that pops up. Would you post a link to the protocol document? I looked up the protocol for the Model 60, which uses a completely different protocol from what you're describing. This is not taught by Crestron in their Systembuilder classes yet but it ought to Alan: That's what all that junk is there for? Who Edizzle: As Alan touched on, are you sure that those are ASCII characters and not a hint that the commands are Hex? We can get to that later. Remember you cannot jam serial macros in Systembuilder so if you need multiple instinces where multiple macros need to be assigned to a single com port ( jamming signals ) you will need to be creative in how you define these modules and you will need to write additonal macros to manage this. Go in to project\edit project header\device support\ and fill out the device family, device type, manufactuer and model fields

#Changing baud rate in a crestron simpl windows module driver#

Add a virtual serial driver for macro connection symbolī. To make in Systembuilder compatable you need toĪ. However, it may have been fixed so you may choose your onw path. The only problem is that when I tried using the second method it did not work so I have only used the first.

#Changing baud rate in a crestron simpl windows module drivers#

The difference between the two SIO drivers is that with the first you cannot name the signals so you have to write down what you have coded on to string 1$, string 2$ and so on whereas the second module allows you to name the signals Or you can place you mouse in the white space of the user database and select "new serial device Otherwise you can use either the Generic Serial serial driver found in equipment view in the Crestron database under Generic\generic serially controlled device If you are using Runco a lot then make a module. I can walk you through it if you'd like, but I'm currently working on a new UI for a 4" fliptop and don't have the time this evening.įirst thing is find out the actual strings you want to send. You should be able to drop in a known good projector module and edit the program in SIMPL, then replace the joins on the good module with your module. I know there is a way to create SB "hooks" in your module, but I've never been a fan thus never took the time to learn it. You're on your own as far as SB integration. You would probably want to add some logic for some pseudo-feedback as well. Everything else can essentially entered into an SIO. I'm not familiar with the particular protocol, but the most complex part of it could be the possibility of a checksum. Once you get into variable feedback for things like lamp hours, color control, etc. It's not that complicated to create a basic module for power/source control.

0 kommentar(er)

0 kommentar(er)